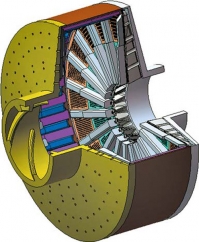

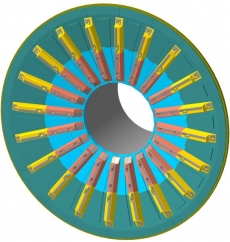

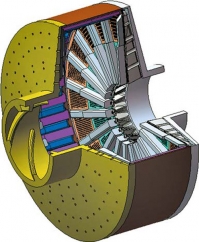

Complete set of rubber lining is used in the autogenous wet-grinding mills at the grinding stage I (raw ore size of up to 400mm) and includes head lining, discharge end lining (grate, elevator), shell lining and set of fixture elements. Rubber lifter bars include directly vulcanized steel armature.

Shell and end lifter bars are fastened with M42, M48 bolts.

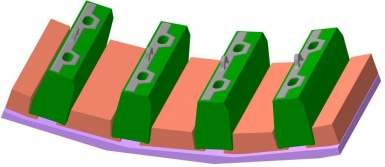

The AWG mill lining features higher section and is available in two designs:

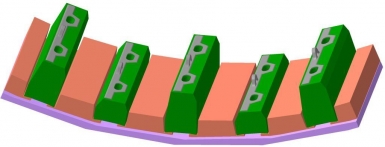

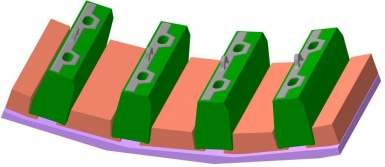

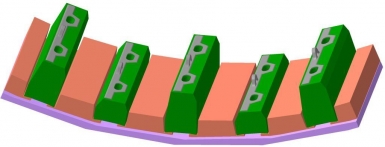

The lining includes rubber plate and combined rubber-metal lifter bar consisting of wear-resistant rubber directly vulcanized onto manganese steel armature.

Metal component of lifter bar absorbs impact loads and provides the secure fastening of lining.

The rubber component of lifter bar protects lifter bar against the abrasion and tightly presses the rubber plate thus preventing washout. Lifter bars are fastened with M42 bolts.

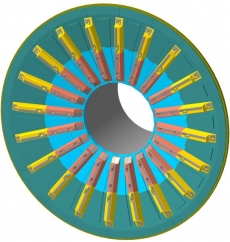

The used rubber grate offers following advantages:

The rubber elevator used for ground product discharge from the mill offers following advantages: