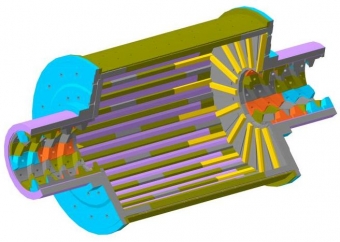

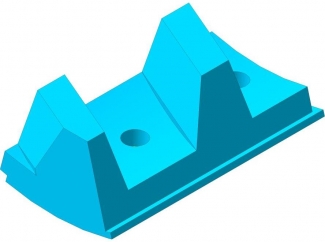

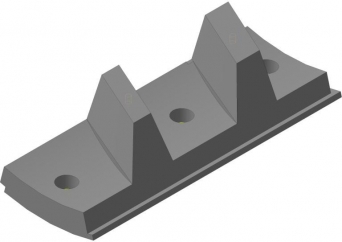

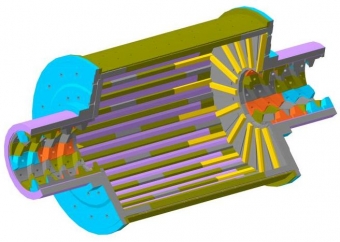

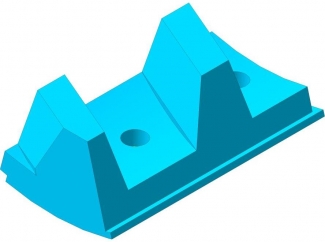

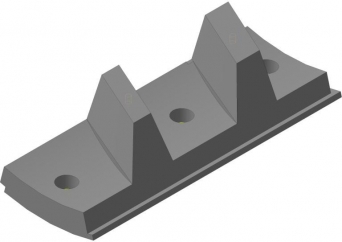

The lining of loading and discharge spouts includes set of finned rubber plates. After the installation in spout, fins form smooth helical surface, which provides the accelerated material feeding to mill in the loading spout, and ball charge return to mill in the discharge spout.

Plates are connected to each other by means of interlocking joint over all face and side surfaces, which allows elimination of gap between plates and provides leak-tight cylindrical surface preventing the internal spout body surface washout.

Plates are fastened to the spout body by means the special-purpose threaded connection.

The loading and discharge spout rubber lining service life is 4 - 6 times as that of equivalent metal armature.

This rubber lining of loading and discharge spouts can be installed in any type of mill.