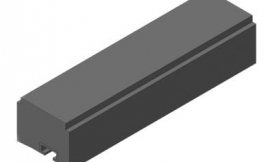

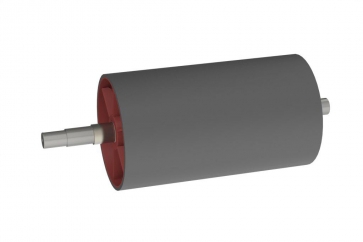

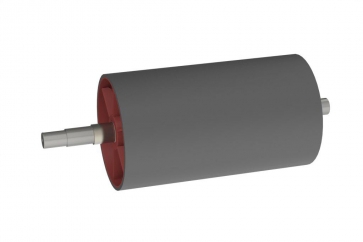

Rubber coating of drums : Product description

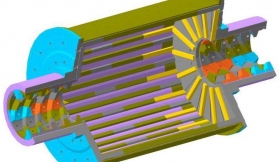

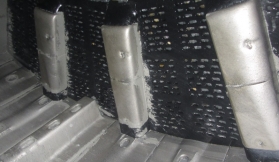

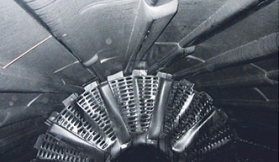

One of lines of “RPE ELAST” Company’s activity is rubber coating of rollers and drums with the use of vulcanization method. Rubber coating allows considerable enhancement of corrosion-resisting properties of working surfaces and improvement of abrasive wear resistance, which substantially extends service life of structure and enhances its overall performance.

In addition, lining acts as shock absorber and maximizes the coefficient of cohesion between drums, rollers and conveyor belt, which reduces belt tension and thus its wear rate. Several factors are taken into consideration in the rubber coating process: structure type and size, rubber coat requirements, rubber mixture composition developed with the use of unique technology by “RPE ELAST”, etc.

Such approach allows quick, proficient and reliable implementation of the set objectives.